The typical operational steps for a control valve include operation, backwashing, brine absorption, slow rinsing, refilling the salt chambers, and routine cleaning. These processes can be summarized into five main stages: work (commonly referred to as water production), backwashing, brine absorption (regeneration), slow rinsing (displacement), and fast rinsing. While most water softening systems follow these basic steps, slight variations may exist depending on specific operational requirements or unique designs. All such systems based on sodium ion exchange rely heavily on these fundamental processes, with adjustments made to the amount of salt used.

During the slow rinsing phase (displacement), raw water is used to gently wash away the remaining brine from the resin after it has passed through with concentrated saltwater. Despite this rinsing, residual calcium and magnesium ions remain attached to the resin’s functional groups. Based on practical experience, this step plays a crucial role in the regeneration process and is often termed "replacement." This phase typically lasts around 30 minutes, aligning closely with the duration of the brine absorption stage.

Fast rinsing occurs after the slow rinse to ensure any leftover salt residues are thoroughly removed. Water is run through the resin at a flow rate similar to normal operating conditions. The end result of this process should produce clean, fully softened water ready for use in automated systems. This phase usually requires 5 to 15 minutes.

Backwashing is essential for maintaining system efficiency. Over time, impurities from untreated water accumulate above the resin layer. By reversing the water flow—entering from the bottom and exiting from the top—the accumulated debris is flushed out, ensuring the resin remains accessible for effective regeneration. This step typically takes 5 to 15 minutes.

Brine absorption (regeneration) involves introducing saltwater into the resin tank. Older models utilize a salt pump, whereas modern automatic units employ an internal injector mechanism activated by water pressure. Studies show that regenerating resin with slow-moving brine yields superior results compared to immersing the resin directly in saltwater. Typically, this regeneration process lasts approximately 30 minutes, followed by a quick rinse lasting 5 to 15 minutes.

Overall, each component of these operations ensures optimal performance while adapting to varying conditions and technological advancements.

Spring Coil Cabinets

Spring Coil Cabinets

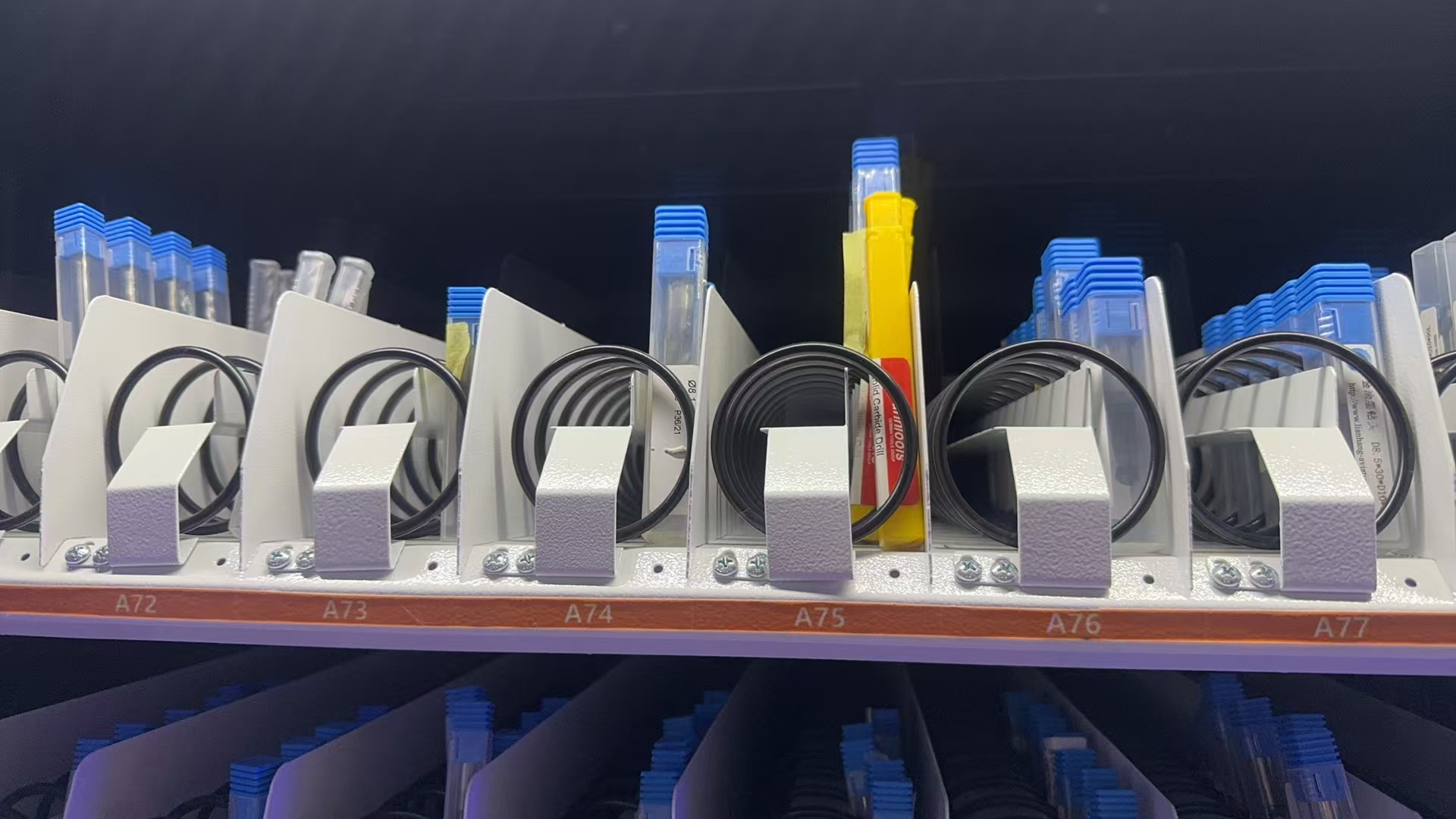

Ideal for dispensing boxed or small packaged items such as cutting tools, gloves, or inserts.

This smart cabinet integrates spring coils and grid compartments with a vertical lifting platform, designed to store and manage various boxed tools, inserts, gloves, and small components. The lift system automatically brings the selected tray to the access window, making it easy and ergonomic for users to retrieve items.

The cabinet supports user authentication (RFID, code, face), real-time inventory tracking, and automatic refill reminders. With flexible configurations and a compact footprint, it’s ideal for tool rooms, CNC workshops, and production lines.

Applications:

CNC tool storage, consumable management, workshop automation, tool distributors.

Features:

Compact design, mixed storage modes, lifting platform, smart access control, customizable layout.

Intelligent Cnc Tool Storage Cabinet,Wooden Drawer Cabinet,Intelligent Equipment Management Cabinets

Jiangsu Xicang Intelligent Technology Co., Ltd. , https://www.xciwarehousing.com