How to Connect Underground Drainage Pipes

An underground drainage system is a crucial component of any property, whether it's residential or commercial. In the UK, every building must be linked to a proper drainage system to prevent potential damage to both the property and the surrounding environment. The most commonly used type of underground drainage pipe in the UK is PVC, which typically features a push-fit connection. This means that you don't need any special tools or solvents to join them; all you have to do is push the pipes together. In this article, we'll walk you through the steps of properly connecting underground drainage pipes, along with the necessary tools and other considerations to keep in mind before starting the project.

Planning the Drainage System

Before you begin connecting the pipes, it's essential to carefully plan out the entire system to avoid having to redo any work later. Ideally, an architect or drainage engineer will provide you with detailed drawings, but if not, you'll need to create a rough sketch of the intended layout. Include the positions of the pipes, their direction, and where they will connect to the main drainage system. Choose the appropriate pipe diameter based on the volume of water flowing through them. Typically, 110mm diameter pipes are used for residential homes, while 160mm pipes are used for larger systems that serve multiple properties. Additionally, make a comprehensive list of all the parts you'll need, such as bends, couplers, end caps, junctions, gullies, and so on. Before you start digging trenches, lay out the pipework in a way that avoids obstacles like trees, pathways, buildings, or existing underground utilities. Ensure that there are no sharp or unnecessary turns. You'll also need to calculate the correct "fall," which refers to the gradual slope required to enable gravity to guide water through the pipes. For more guidance on determining the fall, check out our "Underground Drainage Installation, the Basics" blog post.

Gathering Your Tools

To ensure a successful connection, gather these basic tools beforehand:

- A fine-toothed hacksaw or saw

- A measuring tape

- A marker or pencil

- A rubber mallet

- A chamfering tool

- A trenching shovel

Selecting Materials

For the actual installation, you'll need:

- Underground drainage pipes in the size you've chosen

- Fittings such as bends, couplers, end caps, junctions, etc.

- Pipe lubricant

Excavating the Trench

Dig a trench that's at least 410mm wide (for 110mm underground pipes) and line it with pea shingle. Make sure the trench has at least 300mm of soil covering the top of the pipe once it's placed inside.

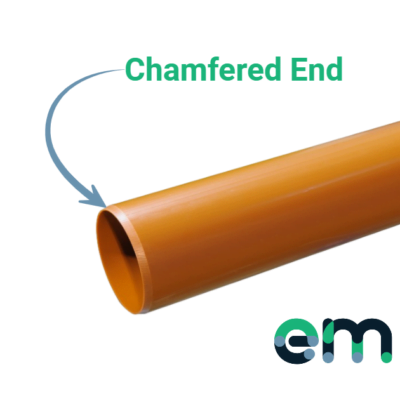

Cutting and Chamfering the Pipes

With your tools and materials ready and your trench dug, measure and cut the pipes to the desired lengths. Use your measuring tape to mark the cuts and then saw the pipes cleanly and straightly. Afterward, chamfer the ends of the pipes using a chamfering tool or a file, and clean them thoroughly to remove any debris from cutting. This ensures smooth connections and prevents leaks caused by damaged seals.

Joining the Pipes

Now comes the exciting part—connecting the pipes. To join two lengths of pipe, you'll either need a drainage pipe coupler, which is a small fitting with two sockets (female ends), or a socket already present on the end of the pipe or fitting. Essentially, the male end (spigot) of one pipe fits snugly into the female end (socket) of another pipe or fitting. Apply pipe lubricant to both the rubber seal of the coupler or socket and the chamfered end of the pipe or spigot. Push the pipe firmly into the socket until it reaches the locator within the fitting. If the connection feels tight, gently tap it into place with a rubber mallet. Repeat this process for each section of pipe and every fitting in the system.

Testing the System

The final step is to test the entire drainage system for leaks before backfilling the trenches. This can be done via an air or water test. If leaks are detected, inspect the connections and tighten them if needed. If tightening doesn't resolve the issue, disassemble the joint and check the rubber seal for any damage, dirt, or debris that might have prevented it from sealing properly.

Once everything checks out and functions correctly, you're finished! It's time to backfill the trenches and move on to the next task!

In summary, connecting PVC underground drainage pipes is relatively simple when you have the right tools and materials. With careful planning and execution, you can complete the job efficiently. If you need additional help or advice, don't hesitate to reach out to us!

The product range of Hongchuang hardware fasteners includes hexagon head screws, full thread and half thread hexagon socket head cap screws, hexagon wood screws, hexagon socket head cap screws, full thread and half thread hexagon socket countersunk head screws, hexagon socket head flange screws, set screws, etc. We provide products conforming to DIN, ANSI and JIS standards.

Stainless steel of grade 304 contains nickel of 8% and chromium of 18% and is the most commonly used grade for the production of fasteners. It possesses an excellent combination of strength, corrosion resistance and fabricability. Fasteners of this grade are being extensively used today in almost every industry.

Metal Screw,Self Tapping Screws,Stainless Steel Screws,Steel Screws

Taizhou Hongchuang Hardware Co., Ltd. , https://www.taizhouhongchuang.com